We transform power

for Aviation and Aerospace

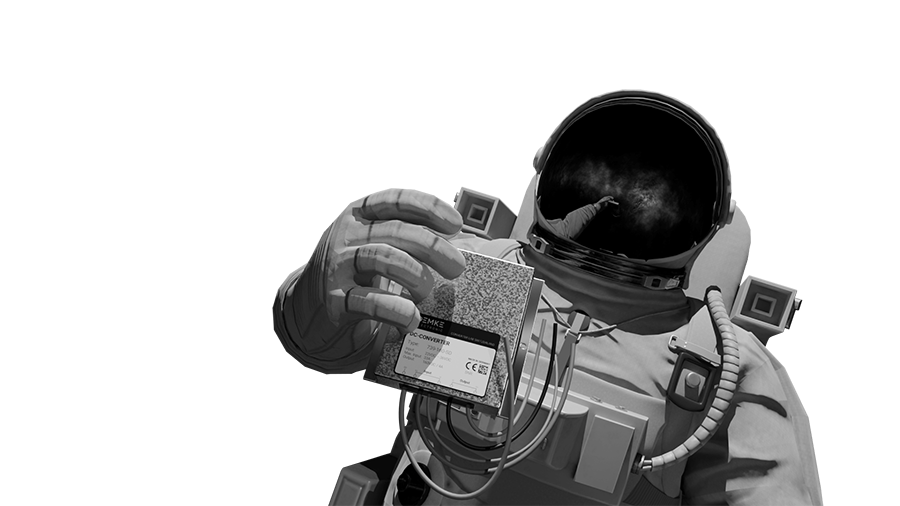

Reliable and Efficient DC/DC Converters for Aerospace Applications

Context and Background

In modern aerospace, DC/DC converters are vital for delivering reliable, efficient power to critical systems like sensors, cameras, and control units, each with its own voltage requirements. These converters maximize the use of limited onboard energy, enhancing both system efficiency and flight duration.

Aerospace demands a compact design due to limited space, along with exceptional robustness and reliability in extreme environments. Whether during rocket launches or in helicopters operating in harsh marine conditions, our DC/DC converters are engineered to withstand intense vibrations, shocks, and significant temperature fluctuations.

With our polyurethane (PU) potting, we provide superior protection against vibrations and impacts, while ensuring excellent environmental resistance, even in high vacuum applications. The converters’ durability is further reinforced by a rugged aluminum housing, making them ideal for challenging aerospace conditions.

DC/DC Converter for Drone Solutions: Creating Space Where There Is None

A client specializing in unmanned vertical take-off and landing (VTOL) systems needed a highly efficient power supply for key electronic components such as sensors, communication systems, and camera units. Given the extremely limited space and the need to operate reliably in harsh weather and saltwater environments, finding the right solution was critical.

Our DC/DC converter 145-24-SD, measuring just 77x52x19 mm and weighing only 165 grams, offers the perfect balance of compactness and performance. With a high efficiency of 95% and full potting for environmental protection, it’s ideally suited for demanding applications like drone search missions in the North Sea, Germany, where thermal cameras are used to locate missing persons in challenging marine conditions.

DC/DC Converters for Re-entry Capsules in Space Travel: The Sky is Not the Limit

Our customer is an innovative company specializing in the development and manufacture of re-entry capsules to safely return cargo from space to Earth. These capsules enable the conduct of research experiments in the field of biosciences. This includes studies with stem cells, organoids, and protein crystallization, which can provide unique insights not possible on Earth.

For the safe re-entry and landing of the capsule, a galvanically isolated DC/DC converter with an output voltage of 150VDC is required. The DC/DC converter 739-92-SD was used as the basis. This converter is powered by a battery and is essential for the capsule's braking system. The supplied voltage activates the parachute system, which safely brings the cargo to the ground upon re-entry into the atmosphere.

During the rocket launch, the device is exposed to extreme vibrations, requiring a robust and vibration-resistant design. Additionally, the DC/DC converter must function reliably in a vacuum. Thanks to the PU potting (polyurethane potting), the device is optimally protected against vibrations and is suitable for use in a vacuum, ensuring flawless operation under the demanding conditions of space travel.

The mission launches from Cape Canaveral, Florida, one of the world's most significant spaceports. The successful development of this DC/DC converter is crucial for the mission and the future conduct of further scientific experiments in space.

This project significantly contributes to expanding the boundaries of biosciences and bringing valuable insights from space back to Earth. By safely returning experiments, research can be advanced that would not be possible under Earth's conditions. With the motto "The sky is not the limit," the project underscores the infinite possibilities that open up through innovation and technology.

Custom Solution for the Future of Autonomous Passenger Transport

A completely new development? No challenge is too big for our expert development team! As part of an ambitious aerospace project, we created a custom device designed to meet the strict requirements of our client. Meeting the high standards of the aviation industry required close collaboration to ensure compliance with all guidelines.

From the initial request to prototype delivery, and the complete provision of all necessary documentation, we managed the project with professionalism, confidentiality and efficiency at every step. What sets this project apart is the remarkably short development timeline - achieved without any prior experience in aviation standards - all while maintaining the highest levels of quality and precision.